Metal Circular recycling

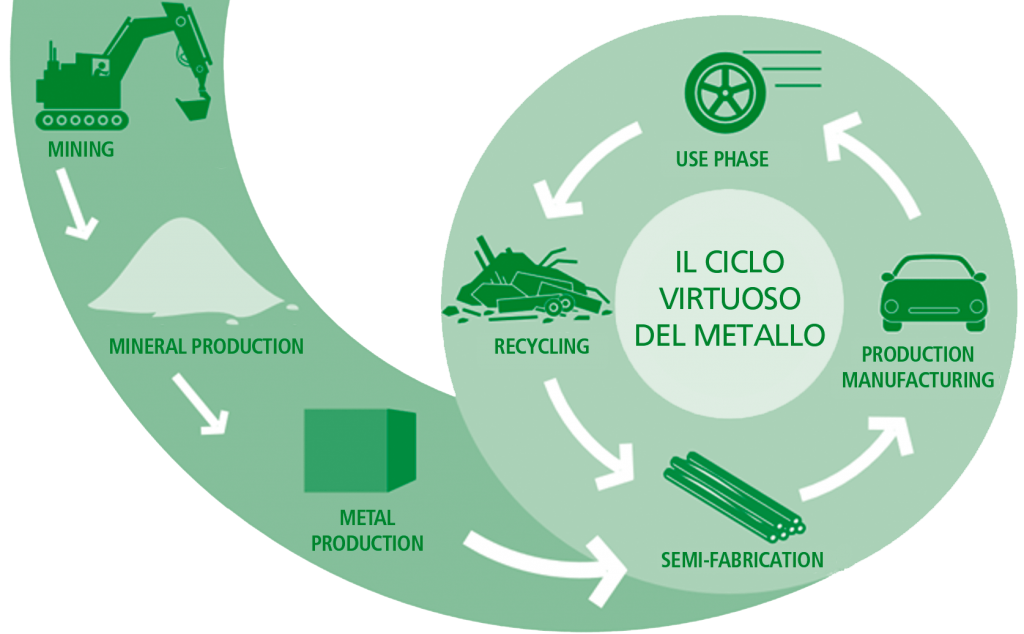

The decarbonisation objective that the European Union has set itself by 2050 is a challenge for the European metals industry. The various supply chains have always been committed to recycling because metals, even in the final phase of their use, retain a high economic, energetic and environmental value. Today, this value reintroduced into society puts recycling chains at the center of the attention of political, social and economic stakeholders and makes them increasingly attractive for investments and new technologies. The national sectors involved are among the first in the world in terms of capacity, innovation and productivity. However, there was no opportunity for an appointment where all the ideas and innovations that will become a current topic in the near future can be found, brought together.

MCR EXPO, Salone delle soluzioni per l’industria del recupero e riutilizzo dei metalli ferrosi e non ferrosi, si propone dal 14 al 16 maggio 2025 quale luogo d’incontro e spazio di visibilità per tutte le imprese che agiscono all’interno delle filiere che costituiscono l’economia circolare dei metalli.

the Metal Scrap Recovery and Recycling Chain

MCR EXPO

COLLECTION TRADE LOGISTICS

ENERGIES

SCRAP TREATMENT

ENVIRONMENT SAFETY CERTIFICATION

MERGER REFINING

ECONOMY MARKETS MARKETS

TECHNOLOGIES

CONSORTIA